TOTSUCAT® LOAD & GO™ Catalyst Sulfiding

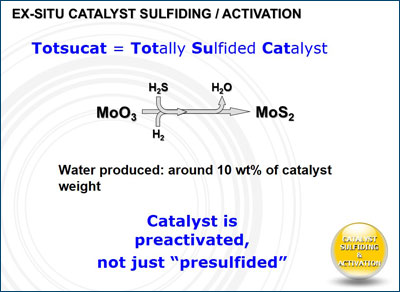

Eurecat’s TOTSUCAT® LOAD & GO™ ex-situ ACTIVATION service successfully activates hydroprocessing catalyst and enables refiners to simplify and accelerate their hydrotreating unit start-up procedure.

Totsucat® activated catalyst can also be passivated to allow for loading under air. Using ex-situ pre-activated catalyst Totsucat® (including Totsucat CFP®) LOAD & GO™ service will save money, reduce start-up time and associated CO2 emission, and it moves the potentially hazardous sulfiding process away from the refinery.

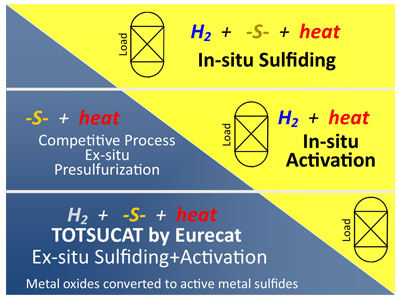

Sulfiding Comparison

Totsucat® Types

Totsucat G: Naphtha

Totsucat D: ULSD

Totsucat E: Vacuum Gas Oil

Totsucat N: Hydrocracking Pre-Treat

Totsucat HC: Hydrocracking

Totsucat TG: Tail Gas

Totsucat SG: Syn-Gas

TOTSUCAT® HC-AP®

Totsucat® HC-AP® eliminates the use of ammonia during hydrocracking catalyst start-up while still controlling the catalyst exotherms.

CFP - Cracked Feed Protection

The CFP (cracked feed protection) process is an extension of the Totsucat® catalyst activation process. The CFP treatment allows for the immediate introduction of cracked stocks instead of waiting 2-3 days. The CFP process includes the catalyst sulfiding, activation, and cracked feed protection.

Loading under air

Eurecat offers various type of Totsucat post treatment allowing safe loading under air. Depending on the catalyst type and the type of application either AirSafe or EZ Load can be proposed.

TOTSUCAT® Benefits

- Fastest and easiest reactor start-ups

- Minimized flaring to met new flare/emissions regulations

- No exotherms upon start-up

- Minimal sour water formation

- No additional H2 needed at startup

- No H2S release into fuel gas

- No odor incidents from sulfiding chemicals

- No handling of sulfiding chemicals

- Catalyst performance is maximized

- Upset conditions will not damage the catalyst

- Totsucat® activation service allows for loading under air

- Certainty of activity level after activation

Catalyst Conditioning

Eurecat preconditioning services can be applied to a wide range of fresh and regenerated materials including nickel, cobalt, copper, chrome, iron and zinc based catalysts, noble metal (palladium and platinum) based catalysts, and adsorbents.

- Highly flexible and efficient facilities (batch/continuous process,

- counter/co-current configuration, wide range of operating conditions,

- and use of various chemical atmospheres.

- Highly trained and experienced staff of technical experts and operators

- Laboratory and pilot plant capability for catalyst operation

- Latest analytical capability for catalyst characterization

- Assurance of quality control during industrial campaigns

- Commitment to high quality and environmental standards

- Co-operation under possible confidential secrecy agreement