We specialize in :

- Catalyst regeneration of NiMo, CoMo, NiCoMo, and NiW

- RAISE® reactivation of Palladium and Nickel hydrogenation catalysts

- Carbon burn-off and stripping of noble metals catalysts prior to metals reclamation

Development of customized catalyst regeneration and activation processes remains an increasingly important part of Eurecat’s services. Contact us about your specific needs. Our laboratory could support the initial evaluation of your catalyst to evaluate the regenerability.

- Activity Testing and Regeneration

- SAS Sample Analyze Segregate Brochure

Catalyst Regeneration

Catalyst regeneration processes utilize different types of batch and continuous-flow equipment to remove carbon and sulfur from spent catalyst.

RAISE® (Raise Activity - Improve Selectivity)

Catalyst Activation for Precious Metal Catalysts

SAS: Sample-Analyze-Segregate

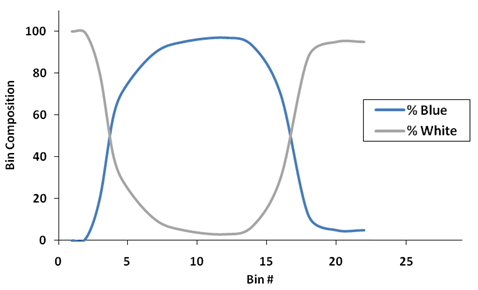

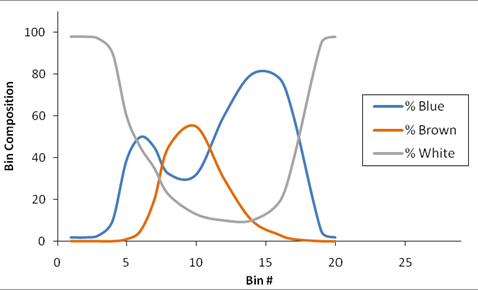

- SAS = Sample – Analyze – Segregate

- Recover clean catalyst based on analysis of each individual bin

- Not just single analysis of composite sample

- Catalyst quality will vary greatly bin-by-bin based on the dump characteristics

Regenerated Catalyst Analysis Data

- Regenerated Catalysts Analysis Data :

- Contaminants

- Physical Characteristics

- Length Distribution

- Catalyst Activity Relative to Fresh for HDS

- Relative Delta Pressure Drop to Fresh (Optional)

Catalyst Rejuvenation

For those refiners who want to maximize their catalyst activity while minimizing their material cost, and environmental footprint, Eurecat can provide the latest in catalyst rejuvenation technologies.

Rejuvenation allows for multiple re-use of all CoMo, NiMo and NiCoMo catalysts, always maximizing activity recovery. This results in less downtime, lower environmental impact lower reactor temperatures, longer cycle lengths, and (above all) minimization of filling costs.

The bottom line is your bottom line. Why spend money on new high-end catalysts when you can re-use the catalysts that you already have for a fraction of the cost?

Eboost- ENCORe - REACT- REVIVAL

Catalyst Dump Videos

Catalyst flow during a dump is not plug flow, but rather a “reverse chimney” flow. In order to accurately determine which bins are contaminated versus clean, the individual bins must be samples and analyzed. This is the Eurecat SAS (Samples-Analyze-Segregate) process.

Click on the video to watch the catalyst dump.